Ensuring Safety and Reliability

When it comes to electrical products, safety and reliability are of utmost importance. Poor quality electrical products can pose serious risks to individuals and properties. Quality control measures play a crucial role in ensuring that Australian electrical products meet the highest safety standards and provide reliable performance.

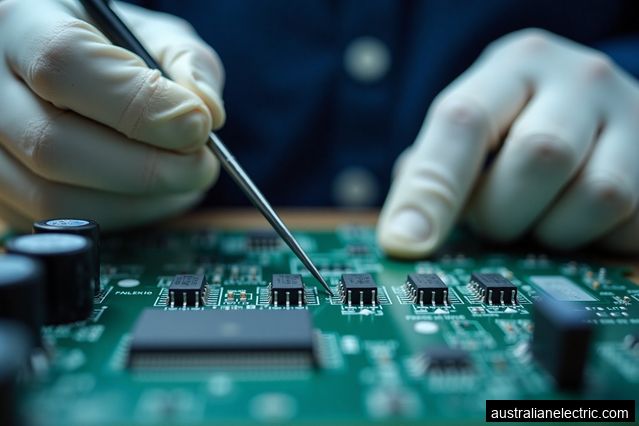

Stringent Testing Procedures

To ensure safety and reliability, Australian electrical products undergo stringent testing procedures during the quality control process. These tests include checks for insulation resistance, voltage withstand, and leakage current. Additionally, products are tested for compliance with Australian standards and regulations, such as AS/NZS 3000:2018 Electrical Installations (known as the Wiring Rules).

Compliance with Standards and Regulations

Quality control ensures that Australian electrical products comply with the relevant standards and regulations. Compliance with these standards is essential to guarantee the safety and reliability of electrical products. The standards set by organizations such as the Australian Communications and Media Authority (ACMA) and the Electrical Regulatory Authorities Council (ERAC) help maintain uniformity and high-quality standards across the industry.

Certification and Markings

Quality control processes involve certification and markings that indicate compliance with Australian standards. For example, the Regulatory Compliance Mark (RCM) signifies that an electrical product meets the necessary safety and electromagnetic compatibility requirements. These certifications and markings provide assurance to consumers and businesses that the products they purchase are safe, reliable, and legally compliant.

Preventing Counterfeit Products

Quality control is crucial in preventing the circulation of counterfeit electrical products in the Australian market. Counterfeit products not only undermine the integrity of legitimate manufacturers but also pose significant safety risks. By implementing robust quality control measures, manufacturers can detect and eliminate counterfeit products, ensuring that consumers have access to genuine and safe electrical products.

Traceability and Supply Chain Management

Quality control processes include traceability and supply chain management systems that help identify and eliminate counterfeit products. These systems enable manufacturers to track the origin and movement of electrical products throughout the supply chain, ensuring that only authentic and compliant products reach the market. By maintaining strong control over the supply chain, manufacturers can protect consumers from the dangers associated with counterfeit electrical products.